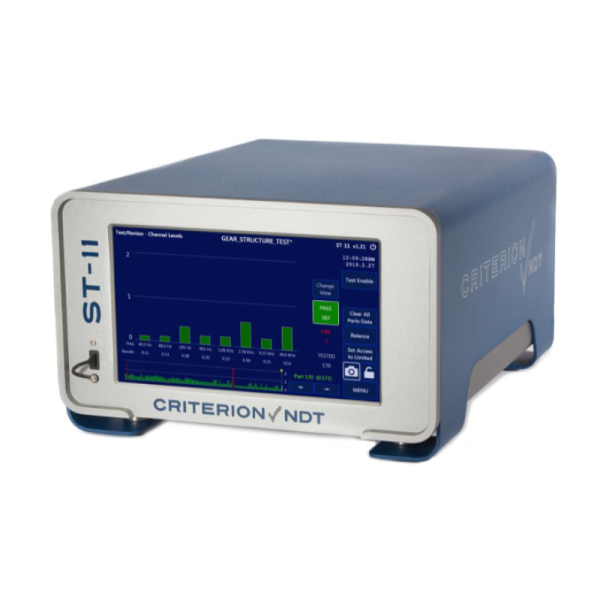

ST-11 Material Structure,Alloy, Thread and Assembly Verification Test Instrument

Quantity

SORT OUT MATERIAL STRUCTURE, HARDNESS AND MATERIAL MIX ISSUES, CONFIRM THREAD QUALITY AND VERIFY CORRECT ASSEMBLY IN REAL TIME

The Criterion NDT ST-11 is a purpose built, multi-frequency material structure test instrument. It was developed to quickly identify and sort products with improper heat treatment and material mix issues.

The Criterion NDT ST-11 is a purpose built, multi-frequency material structure test instrument. It was developed to quickly identify and sort products with improper heat treatment and material mix issues.

Users can also leverage the fast static testing functionality of the ST-11 for thread testing as well as some product assembly verification applications.

Issues such as clogged quench nozzles, loose tooling/fixturing, bent induction coils, incorrect heating cycles, power outages and the like can result in hardness, case depth and case pattern issues that are immediately detectable with the ST-11 on your production line.

An industry leading user interface, coupled with our unique Setup Assist feature, ensures all levels of production personnel can quickly establish ST-11 testing configurations and easily understand the test results.

The ST-11’s Industrial I/O provides the handshaking required to seamlessly work with today’s automation systems.

The ST-11’s modern electronics generate minimal heat, eliminating the need for external fans. This important feature keeps the dirty oily plant atmosphere out, minimizing downtime for repairs and extends the life of the instrument.

Multi-frequency ST-11 verifies material structure and hardness after heat treatment, confirms alloy type and checks threaded hole quality at production line speeds. The ST-11 instrument helps you detect and sort out undesirable heat treat conditions such as shallow or misplaced case as well as others resulting from short heat, delayed quench, short quench, air cooled and no heat. The ST-11 is ideal for testing Automotive Drive Train Components such as Gears, Shafts, Valves, Rings, Bearings, Fasteners, Threaded Blocks and Covers, Assembly Verification and other Safety Critical Items.

ST-11 Features:

- Confirm heat treatment, case depth, material mix and assembly

- Eight test frequencies and data channels help sort out parts with a wide spectrum of potential reject conditions

- Setup Assist feature provides a quick and easy way to customize product specific test configurations

- Industrial I/O works with material handling systems’ PLC’s for easy production integration

- TCP/IP communication allows a variety of additional controls

- Includes TCP/IP Remote Control Apps for use on any Windows PC

- Full Color Touch Screen with our simplified menu provides an intuitive operating experience

- Rugged all aluminum enclosure is designed for tough production environments

- No external fan keeps dirt and oily air out

- Reduces scrap and warranty costs by finding issues during production

- Provides valuable test aspect for the quality of safety critical components

- Clean non-destructive test method

Specification

- Dimensions: 8” tall x 13” wide x 16” deep 20 cm x 33cm x 40 cm

- Weight: 22.2 lbs. (10Kg)

- Frequency Range: 5 Hz to 4 MHz

- Probe Drive: 0.1 to 20 Volts

- Sample Rate: 20,000 Samples/Second

- Display Type: 10.1 inch Touch Screen

- USB Ports: 3

- Universal AC Power: Yes

- Result Views: Large “Pass” / “Fail” Text, Eight Channel Columns, Eight XY Ellipse Alarms

- I/O: TCP/IP, RS-232, and Discrete 26 Pin